Your How to make a trailer axle images are ready in this website. How to make a trailer axle are a topic that is being searched for and liked by netizens now. You can Find and Download the How to make a trailer axle files here. Get all free photos and vectors.

If you’re looking for how to make a trailer axle pictures information connected with to the how to make a trailer axle keyword, you have visit the right blog. Our site always gives you suggestions for seeking the maximum quality video and image content, please kindly search and find more enlightening video articles and graphics that fit your interests.

How To Make A Trailer Axle. If you are planning to include a suspension on the trailer the linked. The way to tell which areas to reinforce is by making the trailer flex. Good weld penetration with no porosity or undercut is required to ensure the strength and integrity of the axle is not compromised. Plenty of trailer axles have been made this way with short stub axles and pipe usually the pipe runs right through the U bolts but wouldnt have to in this case because of the length of the remaining axle.

Pin On Mini Bike From pinterest.com

Pin On Mini Bike From pinterest.com

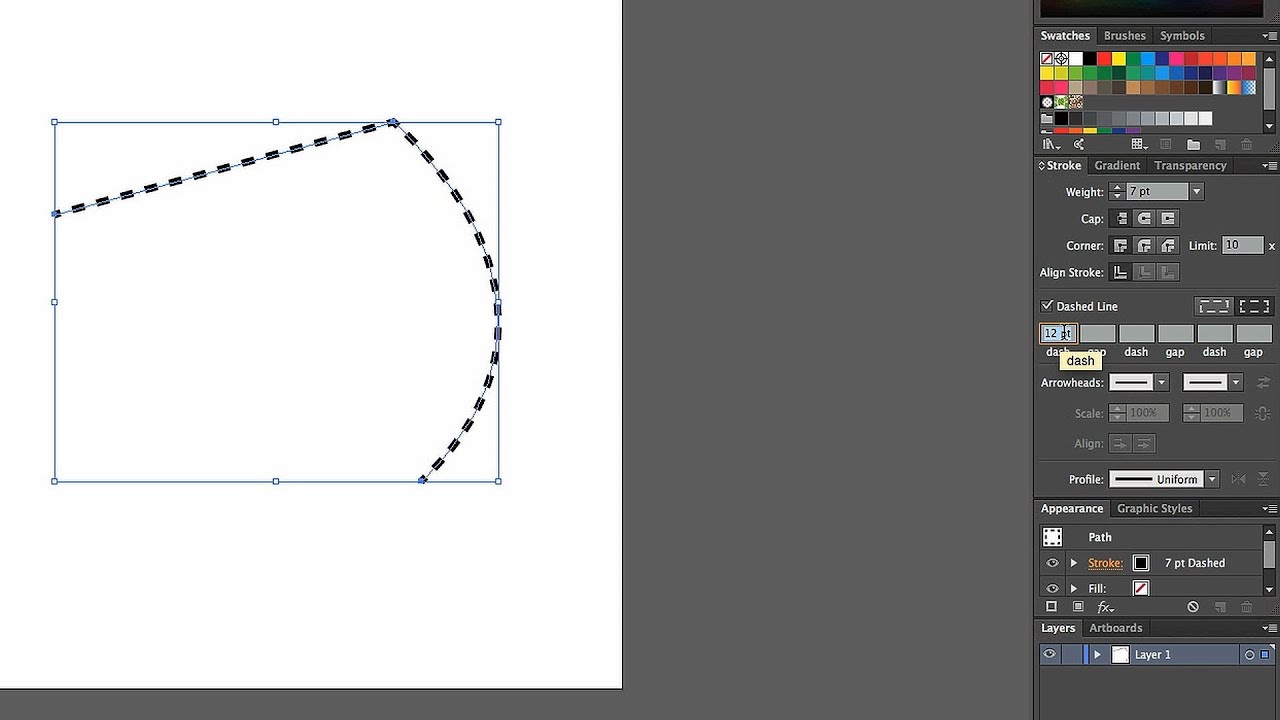

For an 87 hub-face with straight spindles you would need a 765 tube after cutting. I attached a picture that details the process. Plenty of trailer axles have been made this way with short stub axles and pipe usually the pipe runs right through the U bolts but wouldnt have to in this case because of the length of the remaining axle. If you are planning to include a suspension on the trailer the linked. Building a Trailer Axle. 25th May 2011 1213 PM.

6K 7K D60 D70 Axles.

6K 7K D60 D70 Axles. Plenty of trailer axles have been made this way with short stub axles and pipe usually the pipe runs right through the U bolts but wouldnt have to in this case because of the length of the remaining axle. Without the usual RD and testing performed by axle and trailer manufacturers you will be in unknown territory as to the actual weight capacity of your project. In order to raise a leaf sprung axle without changing the orientation of the axle tube in relation to the leaf spring pack you really only have one option which is the Lippert Components Tandem Axle Lift Kit part LC407131 and this provides 2 of lift unlike the axle overunder kits which provide upwards of 3-4 of lift. Check out the following designs find the right size for your needs start building and enjoy the benefits of having a trailer crafted by your own hands. Also this puts a torque on the main beams so make sure that is offset with cross bars.

Source: pinterest.com

Source: pinterest.com

Plenty of trailer axles have been made this way with short stub axles and pipe usually the pipe runs right through the U bolts but wouldnt have to in this case because of the length of the remaining axle. If you are planning to include a suspension on the trailer the linked. Building a Trailer Axle. These can make it easier to build a trailer with a low deck height. Also this puts a torque on the main beams so make sure that is offset with cross bars.

Source: id.pinterest.com

Source: id.pinterest.com

February 14 2020 - by Arfan - Leave a Comment. 6K 7K D60 D70 Axles. Building Trailer Axles NOTE - Building your own axles should only be undertaken by a skilled and proficient welder equipped with a heavy duty industrial strength welding machine. For determining the tube length needed after cutting start with the desired hub-face measurement and subtract 105 for straight 6000-7000 or 1475 for drop 6000-7000 standard spindles. Twin Torsion Axles Walking Beam Tandem Trailer.

Source: pinterest.com

Source: pinterest.com

If you are planning to include a suspension on the trailer the linked. How to make roll-up axle trailer jacks - YouTube. If you are planning to include a suspension on the trailer the linked. Without the usual RD and testing performed by axle and trailer manufacturers you will be in unknown territory as to the actual weight capacity of your project. Good weld penetration with no porosity or undercut is required to ensure the strength and integrity of the axle is not compromised.

Source: cz.pinterest.com

Source: cz.pinterest.com

I attached a picture that details the process. Building a Trailer Axle. Twin Torsion Axles Walking Beam Tandem Trailer. Determining the location of the axles on your triple axle trailer can be difficult but basically you want to locate the axles so that the tongue weight of the trailer is 10 percent of the total trailer. I attached a picture that details the process.

Source: pinterest.com

Source: pinterest.com

A long trailer will probably have taller main beams which increase trailer deck height. I attached a picture that details the process. Test it by jumping up and down on a corner of the trailer and see if ONE corner moves a lot more than the others. Please note for a single axle trailer application I do recommend using. 6K 7K D60 D70 Axles.

Source: pinterest.com

Source: pinterest.com

Good weld penetration with no porosity or undercut is required to ensure the strength and integrity of the axle is not compromised. In order to raise a leaf sprung axle without changing the orientation of the axle tube in relation to the leaf spring pack you really only have one option which is the Lippert Components Tandem Axle Lift Kit part LC407131 and this provides 2 of lift unlike the axle overunder kits which provide upwards of 3-4 of lift. Sorry its only a little pic but you get the idea. Lets say you want an 89-inch axle rated for 3500-lbs that uses 5 on 4-12 bolt pattern idler hubs hubs without brakes. Twin Torsion Axles Walking Beam Tandem Trailer.

Source: pinterest.com

Source: pinterest.com

You can use the filters on the page to narrow the results based on the characteristics you need. The dual axle utility trailer is suitable to be towed by a vehicle with either a Class 2 or heavier hitch and this trailer is the real workhorse of the utility trailers here. Determining the location of the axles on your triple axle trailer can be difficult but basically you want to locate the axles so that the tongue weight of the trailer is 10 percent of the total trailer. Good weld penetration with no porosity or undercut is required to ensure the strength and integrity of the axle is not compromised. Building a Trailer Axle.

Source: pinterest.com

Source: pinterest.com

Without the usual RD and testing performed by axle and trailer manufacturers you will be in unknown territory as to the actual weight capacity of your project. Please note for a single axle trailer application I do recommend using. Without the usual RD and testing performed by axle and trailer manufacturers you will be in unknown territory as to the actual weight capacity of your project. Check out the following designs find the right size for your needs start building and enjoy the benefits of having a trailer crafted by your own hands. I attached a picture that details the process.

Source: pinterest.com

Source: pinterest.com

I attached a picture that details the process. How to make roll-up axle trailer jacks - YouTube. Good weld penetration with no porosity or undercut is required to ensure the strength and integrity of the axle is not compromised. These can make it easier to build a trailer with a low deck height. The way to tell which areas to reinforce is by making the trailer flex.

Source: pinterest.com

Source: pinterest.com

For determining the tube length needed after cutting start with the desired hub-face measurement and subtract 105 for straight 6000-7000 or 1475 for drop 6000-7000 standard spindles. A long trailer will probably have taller main beams which increase trailer deck height. Also this puts a torque on the main beams so make sure that is offset with cross bars. Walking beam axle trailer trailer wheel spindles walking beam tri axle walking beam suspension great tandem trailer walking beam. How to make roll-up axle trailer jacks - YouTube.

Source: pinterest.com

Source: pinterest.com

For determining the tube length needed after cutting start with the desired hub-face measurement and subtract 105 for straight 6000-7000 or 1475 for drop 6000-7000 standard spindles. For determining the tube length needed after cutting start with the desired hub-face measurement and subtract 105 for straight 6000-7000 or 1475 for drop 6000-7000 standard spindles. Good weld penetration with no porosity or undercut is required to ensure the strength and integrity of the axle is not compromised. How to make roll-up axle trailer jacks. How To Build A Walking Beam Axle Trailer.

Source: pinterest.com

Source: pinterest.com

Also this puts a torque on the main beams so make sure that is offset with cross bars. Twin Torsion Axles Walking Beam Tandem Trailer. Thats a trailer that needs stiffening. Good weld penetration with no porosity or undercut is required to ensure the strength and integrity of the axle is not compromised. Building a Trailer Axle.

Source: pinterest.com

Source: pinterest.com

Determining the location of the axles on your triple axle trailer can be difficult but basically you want to locate the axles so that the tongue weight of the trailer is 10 percent of the total trailer. How To Build A Walking Beam Axle Trailer. Typically on triple axle trailers the center axle will be located 60 percent of the way from the. If space is available the axle mounts might be placed just off to the side of the main beams vertically up a little. Determining the location of the axles on your triple axle trailer can be difficult but basically you want to locate the axles so that the tongue weight of the trailer is 10 percent of the total trailer.

Source: pinterest.com

Source: pinterest.com

Lets say you want an 89-inch axle rated for 3500-lbs that uses 5 on 4-12 bolt pattern idler hubs hubs without brakes. For determining the tube length needed after cutting start with the desired hub-face measurement and subtract 105 for straight 6000-7000 or 1475 for drop 6000-7000 standard spindles. How to make roll-up axle trailer jacks - YouTube. Helpful expert reply by. Twin Torsion Axles Walking Beam Tandem Trailer.

Source: pinterest.com

Source: pinterest.com

The dual axle utility trailer is suitable to be towed by a vehicle with either a Class 2 or heavier hitch and this trailer is the real workhorse of the utility trailers here. How to make roll-up axle trailer jacks - YouTube. Building Trailer Axles NOTE - Building your own axles should only be undertaken by a skilled and proficient welder equipped with a heavy duty industrial strength welding machine. These can make it easier to build a trailer with a low deck height. Lets say you want an 89-inch axle rated for 3500-lbs that uses 5 on 4-12 bolt pattern idler hubs hubs without brakes.

Source: pinterest.com

Source: pinterest.com

Good weld penetration with no porosity or undercut is required to ensure the strength and integrity of the axle is not compromised. These can make it easier to build a trailer with a low deck height. February 14 2020 - by Arfan - Leave a Comment. Building a Trailer Axle. Or perhaps when jumping on one then the opposite corner moves a lot.

Source: pinterest.com

Source: pinterest.com

These can make it easier to build a trailer with a low deck height. You can use the filters on the page to narrow the results based on the characteristics you need. Twin Torsion Axles Walking Beam Tandem Trailer. Building a Trailer Axle. Or perhaps when jumping on one then the opposite corner moves a lot.

Source: pinterest.com

Source: pinterest.com

If playback doesnt begin shortly try. Building Trailer Axles NOTE - Building your own axles should only be undertaken by a skilled and proficient welder equipped with a heavy duty industrial strength welding machine. Good weld penetration with no porosity or undercut is required to ensure the strength and integrity of the axle is not compromised. Lets say you want an 89-inch axle rated for 3500-lbs that uses 5 on 4-12 bolt pattern idler hubs hubs without brakes. Building a Trailer Axle - Dropper Plates The simplest and quickest way to build a dropped axle is to use pre fabricated dropper plates.

This site is an open community for users to submit their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site value, please support us by sharing this posts to your favorite social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title how to make a trailer axle by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.